Acid mordant (acid adjustment)

Model No.︰-

Brand Name︰QianTai Chemicals

Country of Origin︰China

Unit Price︰-

Minimum Order︰1 pc

Product Description

Acid mordant (acid adjustment) is a textile auxiliary used to enhance the wet fastness of nylon and fluorescent dyed nylon fabrics. It prevents color changes under sunlight and other treatments, with minimal hardening effect on touch. Notably, this mordant has excellent solubility, low viscosity of the product, and high operational efficiency. Theoretically, it also works for other fluorescent dyed fabrics such as cotton and polyester.

【Properties】

Composition: Aromatic sulfonic acid salt condensate

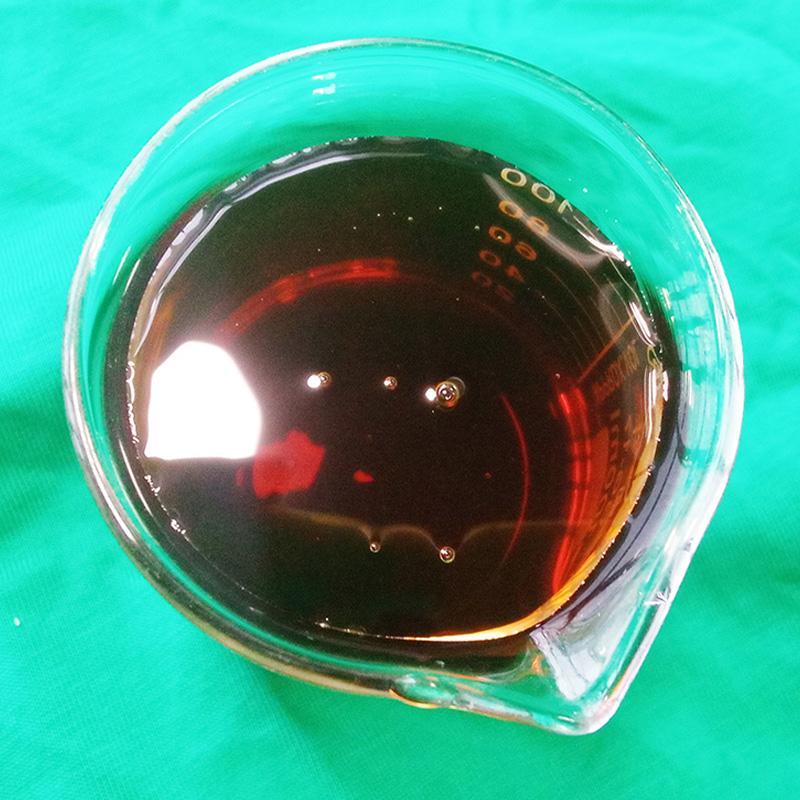

Appearance: Brown transparent liquid

pH Value: 9±1

Ionicity: Anionic

Solubility: Easily soluble in water

【Product Features】

1. Provides excellent wet fastness for acid dyes on polyamide fibers.

2. Prevents color changes in polyamide fibers under sunlight and other treatments.

3. Minimal adverse effects on the properties and feel of polyamide fibers.

4. Excellent solubility with low viscosity of the product, resulting in high operational efficiency.

【Usage Method】

The usage amount of the acid mordant varies depending on the type, form, dye concentration, dyeing method, and required fastness of the treated material. However, the following method serves as a reference:

Light colors: 1.0~2.0% o.w.f.

Medium colors: 2.0~3.0% o.w.f.

Dark colors: 3.0~4.0% o.w.f.

Treatment bath: Hac 0.5~1g/L, 70℃ boil×20~30min treatment

Specific processes follow your company's existing procedures.

【Performance Testing】

Various fastness tests are conducted as follows:

Test fabric: Nylon fabric

Mordant: X% o.w.f.

Dye: Three types of fast acid dyes

① NYLOSAN Golden Yellow N-48L 1% o.w.f.

② NYLOSAN Red N-GZS 1% o.w.f.

③ NYLOSAN Blue N-GFL 3% o.w.f.

【Processing Conditions】

Mordant treatment (liquor ratio 1:10) at 70℃ for 20 minutes → Washing → Drying (120℃ for 2 minutes) → Setting (170℃ for 1 minute)

【Precautions】

1. Conduct small sample tests beforehand to determine suitable dosage.

2. If used in combination with other finishing agents, compatibility tests should be done in advance.

【Storage and Packaging】

1. Store in a cool, dry, well-ventilated area, protected from sunlight and rain, with a shelf life of six months.

2. Polyethylene plastic drums with inner plastic bags, each drum containing 125KG.

【After-sales Service】

We provide comprehensive after-sales service, including product consultation, technical support, and maintenance, ensuring that any issues during use are promptly resolved. If needed, we can also offer customized solutions based on specific customer requirements to meet diverse personalized needs.

Product Image